Deep-Draw Metal Stamping

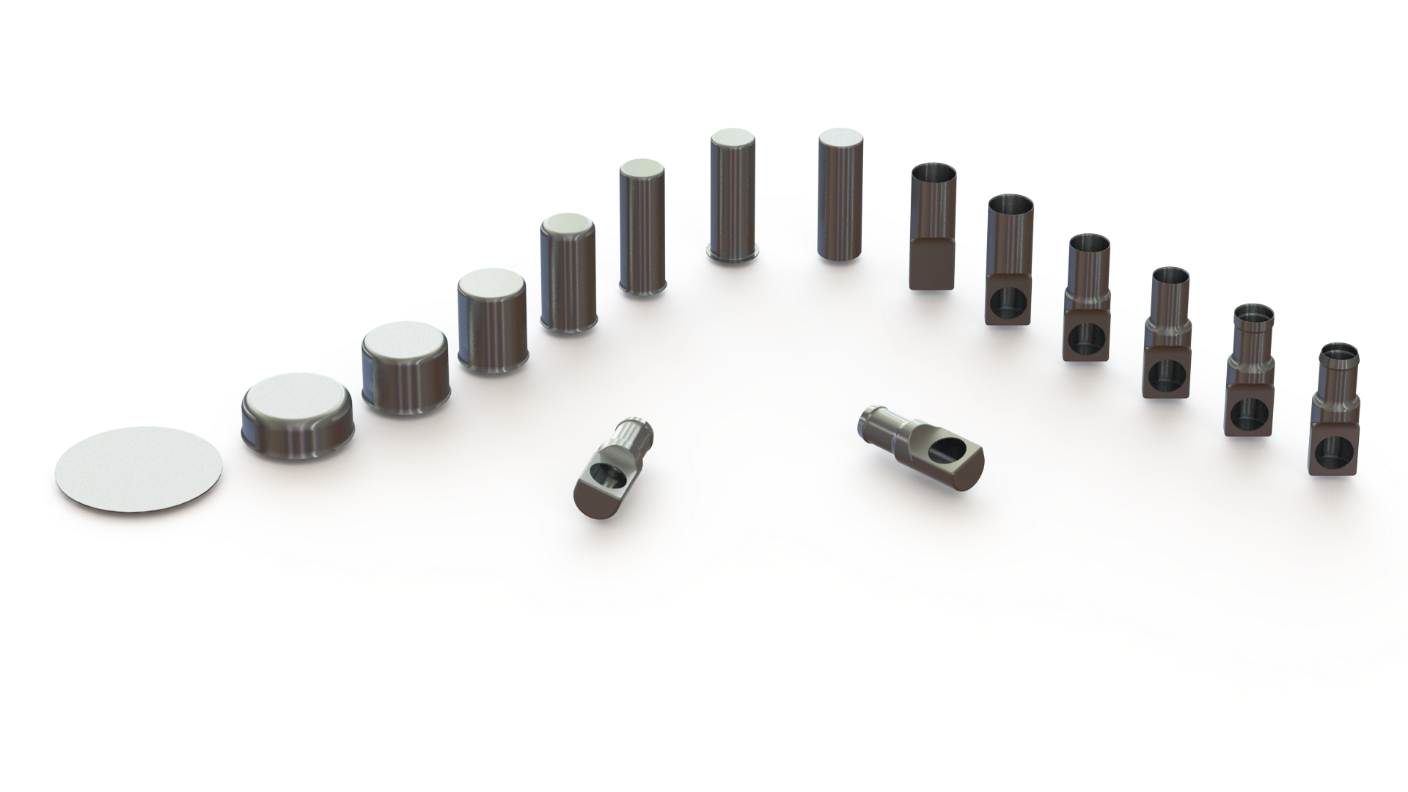

Deep-draw stamping is a high-speed, high-value shape transformation process in which sheet metal is drawn into a forming die to produce round, square or irregularly shaped parts.

Deep-draw stamping is typically done using a transfer press. This process starts with a blank trimmed from the strip of steel which is then transferred station-to-station via a mechanical transfer system, steadily forming the steel into a finished part. Transfer press technology provides an opportunity to stamp extra content into the part due to the part being free from the strip of metal during forming.

This picture illustrates the process, starting with the flat blank on the left and culminating after 13 forming stations with the finished part on the right.

PRODUCTION STARTS HERE

Have a new project in mind? Contact our team to find out how JMS Incorporated can add value to your unique design.