Deep Draw Stamping

Deep-draw stamping is a high-speed, high-value shape transformation process in which sheet metal is drawn into a forming die to produce round, square or irregularly shaped parts.

Deep-draw stamping is typically done using a transfer press. This process starts with a blank trimmed from the strip of steel which is then transferred station-to-station via a mechanical transfer system, steadily forming the steel into a finished part. Transfer press technology provides an opportunity to stamp extra content into the part due to the part being free from the strip of metal during forming.

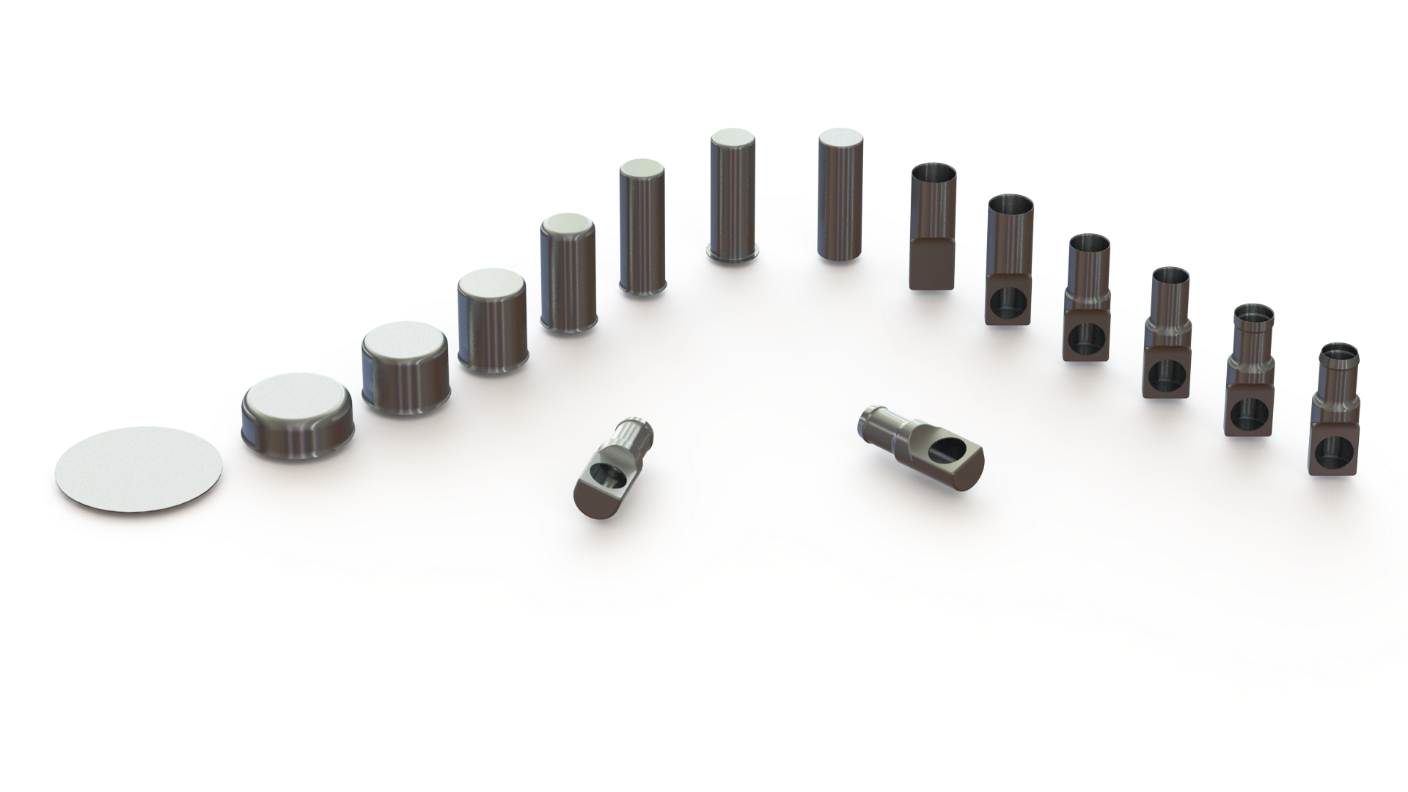

This picture illustrates the process, starting with the flat blank on the left and culminating after 13 forming stations with the finished part on the right.

Superior service

With a global reach and local presence, our goal is to effectively support customer needs. We are committed to building a lasting impact with our clients and suppliers, beginning with the initial partnership and trust that is shared. Our expertise in supply chain management qualifies us to systematically source materials and handle logistics, allowing JMS to offer accurate lead-times and deliver components all over the globe.

High Volume Production, Unmatched Dependability

Our facility is equipped with industry-leading machinery, designed for high-volume production. We’ve invested in cutting-edge technology, combining both engineering and manufacturing principles to deliver deep-drawn components in large quantities, without compromising quality or precision.

It Begins with Quality

JMS Incorporated is proud to hold certifications that represent our attention to detail, understanding the importance of quality, safety, and financial responsibility as a metal stamping supplier. From the design stages to final inspection, we ensure customer requirements are nominally achieved and maintaining the highest industry standards.