Adding Value to Metal

An Innovative Leader in Deep Draw Stamping

Engineering, Manufacturing, and Quality Excellence

“Adding Value to Metal” goes beyond our ability to manufacture tightly-toleranced components. At JMS, our dedication lies in advancing our customers’ business through innovative engineering and unwavering commitment to consistent quality. With a client base serving the automotive, appliance, medical, and agricultural markets, we have a balanced portfolio and business segment expertise across various industries, with future expansion into additional fields.

Contact our team to find out how we can provide value to your unique project.

Built On Experience

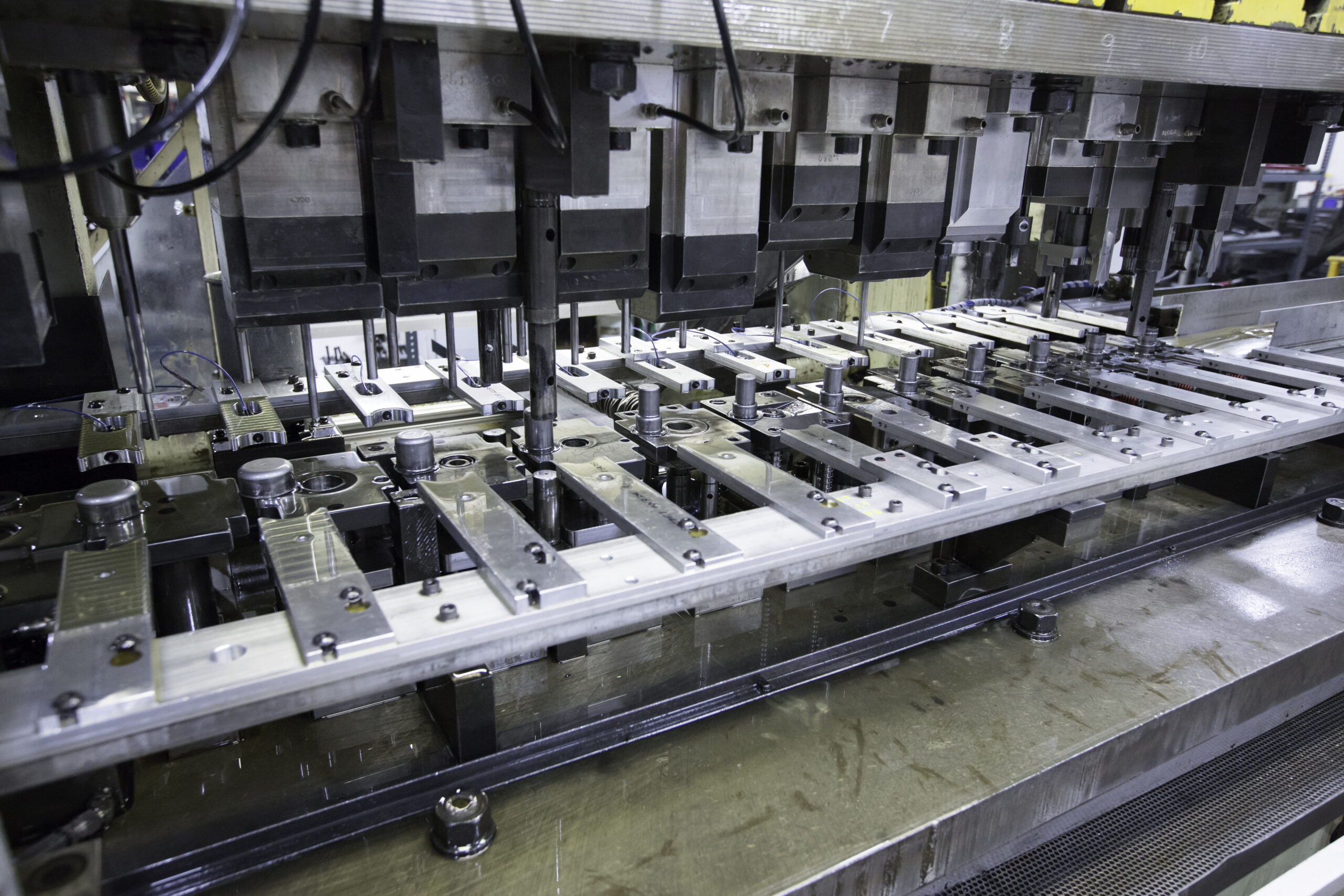

From our facility in Holland, Michigan, we supply stamped components to customers located around the world. Our stampings are also critical components to products found in a diverse set of industries. The efforts of our entire team contribute to our position as a high volume, high quality supplier of engineered stampings. At JMS, we are considered a specialist in deep-drawn stampings built around our core of U.S. Baird-style transfer presses. Additionally, we offer comprehensive capabilities in our progressive die department, ensuring high-quality and efficient production.

We continually enhance our ability to manage all of our new projects right from the very start inside our own organization: from initial design and FEA simulation, to tool making, prototyping and full project management. We have grown our place in the deep-draw stamping industry since our start in 1994 by keeping our focus on producing quality components and providing customers with competitive pricing.

Products and Processes

Deep Draw Stamping

- High Speed

- High Volume

- Allows Complex Forming

Progressive Die Stamping

- High Speed

- High Volume

- Continuous Metal Strip

Assembly

- Multi-Piece Products

- Build-To-Print

- Numerous Joining Capabilities

Simulation and Product Engineering

- Utilization Of DEFORM® Simulation Software

- Skilled In-House Engineering Experts

- 2D and 3D Analytics

Stamping Specifications

Through feasibility studies and testing, JMS will determine the most efficient and cost-effective method of production.

35 Stamping Presses

Transfer & Progressive Die Capabilities

Tonnage Range: 25 – 600 Ton

Press Speed: Up to 150 SPM

Material Thickness: 0.010 – 0.189 in. (.025 – 4.8mm)

Materials

Projects may require certain metal specifications, depending on application. Characteristics such as density, thickness, heat treatment, and plating impact tolerance and dictate the decision on material. JMS is experienced stamping with these various metals.

Hot Rolled Steel

Cold Rolled Steel

HSLA

Aluminum

Stainless Steel

ZAM

Copper

Brass

Experience a Smooth Process from RFQ to Mass Production

Contact Us Today

Tell our sales team about your project. Contact a sales representative by website, phone, or email.

We Go to Work

Our creative engineers and advanced quality planning team are ready for your toughest challenges.

The Launch Process

During development, our project team will be in close contact from start to finish.

Our Commitment

Once in production, JMS customer service will champion your needs.

Testimonials

What Sets JMS Apart

With over 30 years in business, the seasoned team at JMS offers unmatched knowledge in the metal forming and stamping industry.

At JMS Incorporated, our journey began in 1989 as a small tool and die facility. Back then, our goal was simple: supply our customers with the high-quality tooling that was necessary for each of their projects. Fast forward to today, and JMS has evolved into a high-volume production manufacturer, thanks to our hardworking and creative staff. We continually find ways to meet our customers’ specifications using the most cost-effective manufacturing solutions. Located in West Michigan, we work with companies all over the world to meet the industry’s needs.

JMS offers a competitive wage, and both second and third shifts receive an additional shift premium. Our work schedule is based on in-person, 8-hour shifts, Monday-Friday, with overtime opportunities for supplemental pay. Quarterly profit sharing is offered to those who qualify. JMS has various advancement opportunities for team members who consistently perform at a high level. If this sounds like the next step in your career, contact us with any questions or complete our online job application form.